Zimbabwe

Lithium boom: Zimbabwe looks to China to secure a place in the EV battery supply chain

Chinese investors have flocked to Zimbabwe to secure lithium supplies, promising local development. But analysts warn Zimbabwe needs more robust governance for communities to reap the benefits.

Andrew Mambondiyani

Author

Bernard Chiketo

Photographer & Videographer

Zimbabwe

Lithium boom: Zimbabwe looks to China to secure a place in the EV battery supply chain

Chinese investors have flocked to Zimbabwe to secure lithium supplies, promising local development. But analysts warn Zimbabwe needs more robust governance for communities to reap the benefits.

Andrew Mambondiyani

Author

Bernard Chiketo

Photographer & Videographer

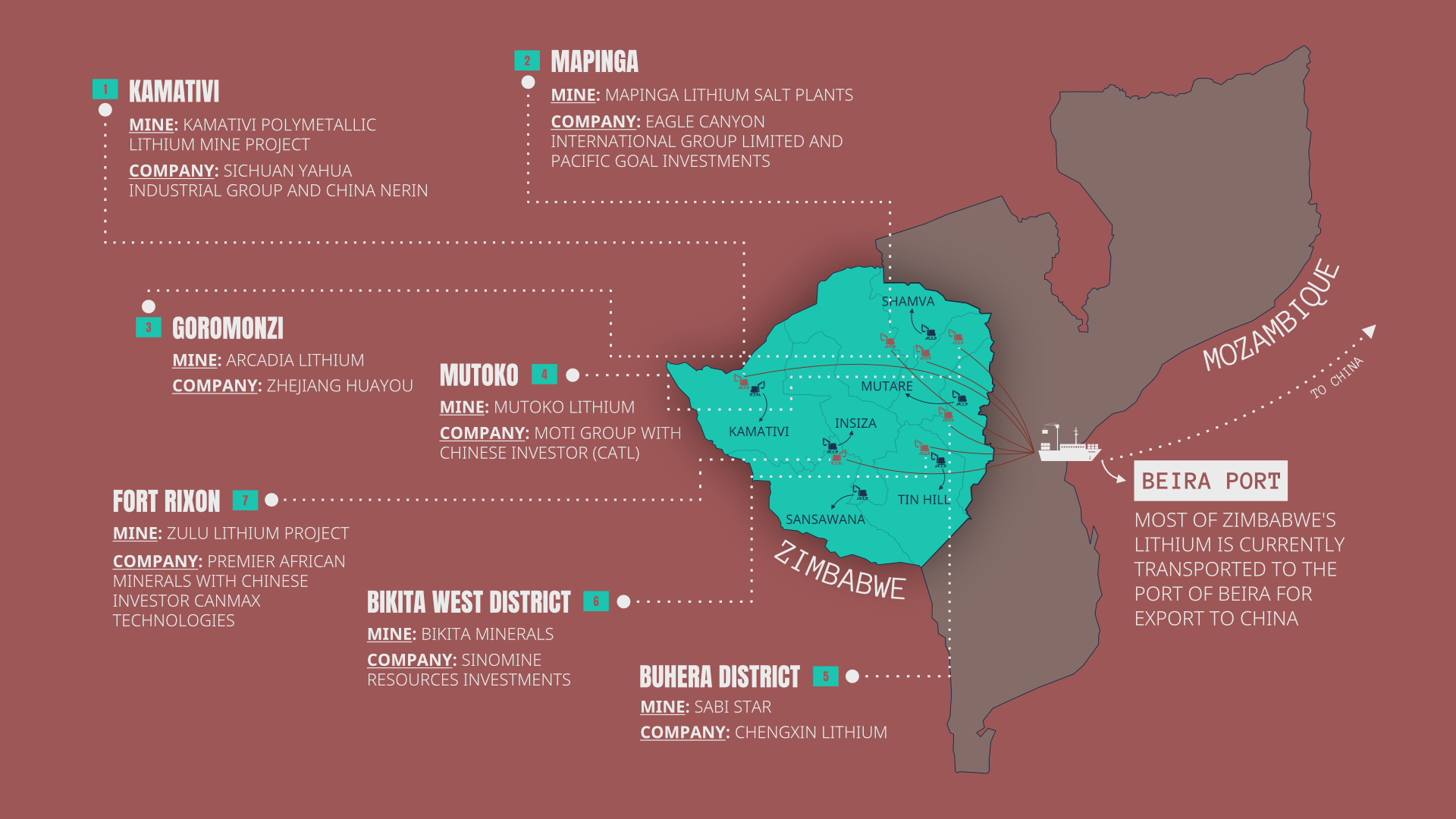

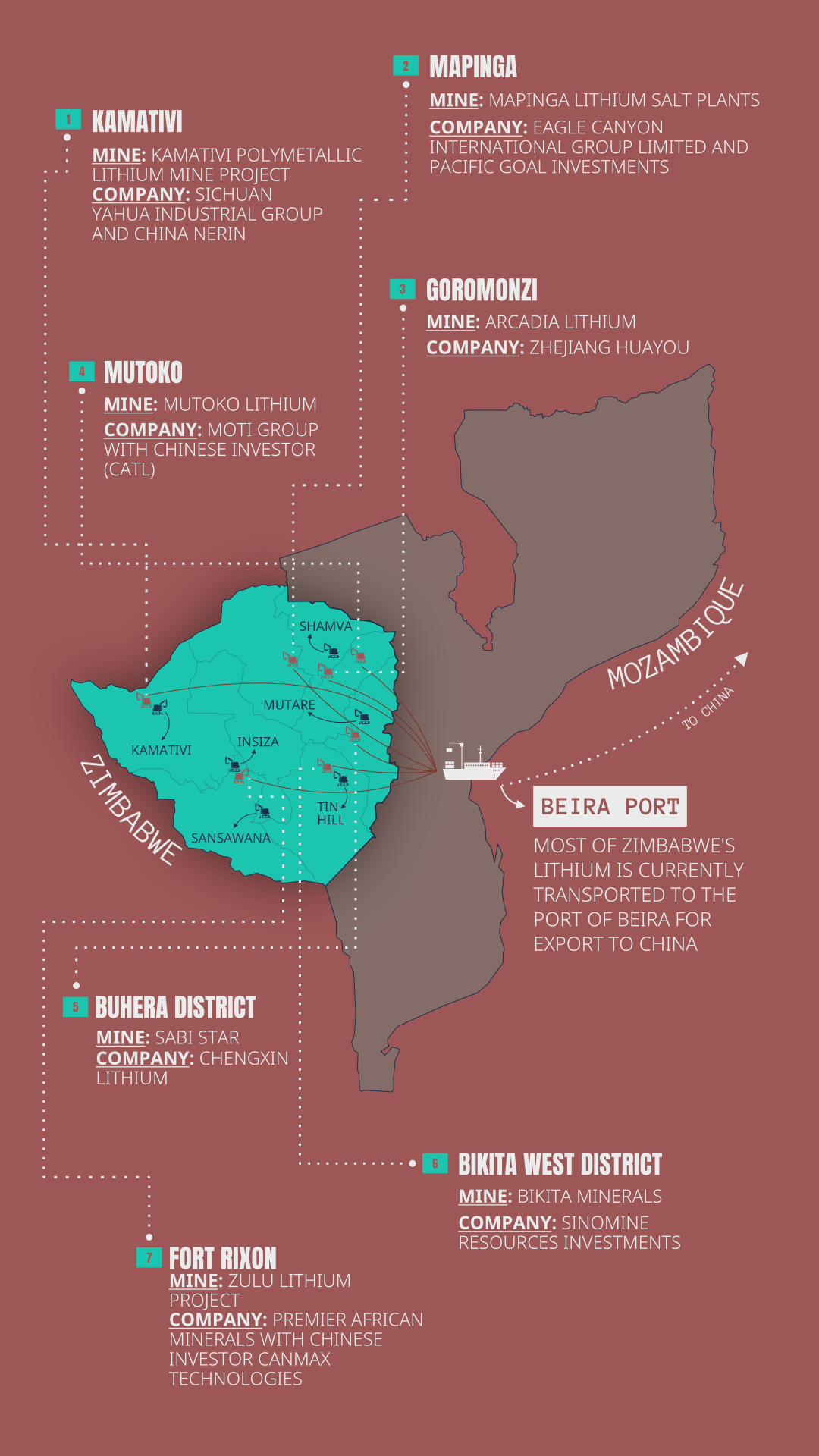

The trucks drive by Mukwasi village on the dirt road linking the Chinese-owned Sabi Star lithium mine to the tarred highway. They travel through the border town of Mutare to the port of Beira in neighbouring Mozambique. From there, the lithium-containing minerals are loaded onto ships and exported to China – the world’s largest manufacturer of lithium-ion batteries.

The dust hung in the air after the trucks’ passage. Mushove and his family were among dozens of households displaced by the $130million-mining project, which began operating in May. They were relocated to new houses built by the mining company about a kilometre from their old homes.

And yet, Mushove is hopeful the mine could “uplift the area and put it on the world map,” he told Climate Home News.

For decades, the vast, hard-rock lithium deposits buried under his home were of little interest to foreign investors. Now, Chinese companies are paying a high price to access Zimbabwe’s reserves – the largest in Africa and among the largest in the world.

A lightweight metal with the ability to store lots of energy, lithium is critical for the manufacture of batteries for electric cars. Global efforts to move away from combustion-engine vehicles have pushed demand for the silvery metal, also known as “white gold”, to soar.

Chinese companies have flocked to Zimbabwe’s untapped reserves of high-grade lithium to shore up the country’s supplies, benefiting from the Southern African nation’s cheap labour and deregulated mining sector. In the past two years, Chinese companies invested over $1.4 billion acquiring lithium projects in Zimbabwe.

And more money is on its way. Last year, Chinese companies were awarded licenses that could see $2.79 billion in investment flow into the country, mostly in the mining and energy sectors.

These investments could turn Zimbabwe into a key player in the global lithium-ion battery supply chain. Chinese battery manufacturing giant BYD could source some of its lithium from Zimbabwe, after buying a stake in the Chinese owners of the Sabi Star mine.

But Zimbabwe’s poor progress on establishing robust resource governance threatens to keep communities like Mushove’s from seeing any of the benefits, analysts told Climate Home.

A truck carrying lithium ore from the Sabi Star mine to the port of Beira, Mozambique, passes by Mukwasi village. Photo: Bernard Chiketo

The race for ‘white gold’

To produce EVs and grid storage batteries at the scale needed to meet global climate goals, lithium demand is expected to increase nine-fold between 2022 and 2030, according to the International Energy Agency – raising the prospect of a supply crunch.

Zimbabwe’s reserves could help ease some of that pressure. The government aims to supply a fifth of the world’s demand.

Eddie Cross, a former advisor to the Reserve Bank of Zimbabwe, is even more optimistic, expecting the country “to command a quarter of global demand in three years,” he told Climate Home. Mining consultancy CRU forecasts Zimbabwe will become the world’s fifth largest producer by 2025 – up from its sixth place last year.

Chinese investments in lithium projects in Zimbabwe

Chinese investments in lithium projects in Zimbabwe

While endowed with vast mineral wealth, Zimbabwe has so far failed to turn its underground riches, including diamonds and gold, into revenues for development. Regulatory gaps, human rights abuses, illegal trade, and alleged corruption have all been barriers.

A recent investigation by NGO Global Witness in Zimbabwe, Namibia, and the Democratic Republic of Congo found that there is a danger of history repeating itself with lithium mining without rigorous screening for corruption and social and environmental harms.

But Zimbabwe’s president Emmerson Mnangagwa is betting on the lithium rush to catapult the country into an upper-middle-income economy by 2030. To achieve this, Mnangagwa aspires to turn Zimbabwe into a battery manufacturing hub.

China’s lithium rush

China towers over the lithium-ion battery supply chain. But its own lithium resources are limited and it has sought to secure access to deposits overseas.

Isolated by the West and slapped with 20 years of sanctions because of human rights violations, Zimbabwe has turned towards China, now the country’s largest foreign investor.

Since the 1950s, China’s foreign policy has been guided by “five principles of peaceful co-existence“, including a commitment not to interfere in another country’s internal affairs. This principle, which encapsulates China’s approach, has set it apart from western investors.

Zimbabwe’s “opacity and disregard for human rights has made it cheap for the Chinese to exploit minerals” in the country, said James Mupfumi, director of the Centre for Research and Development, a local NGO advocating for accountability in the natural resource sector.

Zimbabwean law vests all mineral rights to the president. With no requirements to disclose the beneficial owners of mining projects, “there is no due diligence and parliamentary oversight on Chinese investments,” Mupfumi explained.

“Above all, Zimbabwe requires a government that prioritises public accountability of mineral wealth, not the self-enrichment of a few political elites,” he added.

The ministry of mines did not respond to a request for comment.

‘Lithium is our only hope’

For small-holder farmers living in the vicinity of the Sabi Star mine in Buhera – one of Zimbabwe’s poorest and most water-scarce districts – lithium mining has brought the promise of jobs and a better life.

Around the mine, climate change is causing rainfall to regularly fail, leaving rain-dependent subsistence farmers acutely food insecure. Pastures and water sources for livestock are drying up and only drought resistant Mopane trees and thorny shrubs remain across the parched land.

Abishell Chikunda, a 75-year-old farmer who grows sunflower and groundnuts to sustain himself and his two deaf grandchildren, lives on land adjacent to the mine. Repeated droughts have hurt his income and made life increasingly unbearable.

“We lost most of our cattle due to tick-borne diseases and the lithium is now our only hope,” he said.

With mining claims straddling 2,600 hectares, the equivalent of 4,900 football fields, the Sabi Star lithium mine – one of the country’s largest – has the potential to produce about 900,000 tonnes of raw lithium ore per year.

In 2021, Chengxin Lithium Group, one of China’s largest lithium producers, acquired a majority share in the mine’s operator, Max Mind Investments.

Chengxin Lithium Group’s biggest customers include Chinese companies BYD and CATL, respectively the world’s third and first largest EV battery manufacturers. In 2022, BYD, which recently overtook Tesla as the world’s bestselling EV company, bought a 5% stake in Chengxin – securing lithium supplies.

The promise of local development

Chengxin Lithium said in a statement that the mine would create up to 600 jobs and ease pressure on local employment. The company has installed solar-powered boreholes to supply communities with clean water, renovated school buildings, built a community clinic, and promised to tarmac the dusty road.

Edgars Seenza, secretary for provincial affairs and devolution for the area, is bullish that lithium mining will turn around the region and the country’s fortunes.

“If you look at what the company has done even before they started mining, it shows how serious [it] is,” Seenza told Climate Home.

But not everyone sees it that way. Noah Manhidza, Mukwasi village’s traditional leader, told Climate Home more than 100 families have been displaced by the mine. The company reported that 40 households were evicted, counting members of different families living in the same house as one.

Wonder Mushove stands in front of his former home. Photo: Bernard Chiketo

The borehole dug by the company last year to provide the village with clean water has dried up, and a local dam used by villagers as a water source for livestock was annexed during the mine’s construction. The company has promised to replace both water sources but is yet to do so.

The number of local youths employed by the mine has also been disappointing, said Manhidza. “From a list of more than 20 job seekers, which we submitted to the company, only seven got jobs,” all working as unskilled labourers, he said. Skilled workers come from China and the capital Harare.

Local workers are paid the mining sector’s minimum wage – at least $350 per month, according to local trade unions.

“But their working conditions are still at minimum standards,” said Justice Chinhema, general secretary of the Zimbabwe Diamond and Allied Minerals Workers Union. The union, he said, will work to ensure the company provides medical, pension, and funeral insurance.

Dangerous working conditions have plagued Zimbabwean mines. Local media reports recently alleged that two workers died because of unsafe conditions at another Chinese-run lithium mine.

Chengxin Lithium told Climate Home most local recruits were employed in a large-scale enterprise for the first time and that all employees received safety and skills training. It said it will uphold its social responsibility and strive to “make greater contributions to this land”.

The processing challenge

Last year, as the Chinese-led scramble for Zimbabwe’s lithium resources intensified, the government banned the export of raw lithium ore, requiring miners to start processing the mineral in-country in the hope of cashing in on higher-value exports.

Companies investing in processing infrastructure are currently exempt from the ban, and truckloads of raw ore are reportedly being illegally smuggled out of Zimbabwe because of poor enforcement.

However, Chinese companies invested millions of dollars in building first-stage processing plants – raising their stake in the country’s nascent lithium industry.

At Sabi Star, a $45million processing plant will start separating the lithium-rich minerals from solid rocks to produce 300,000 tons of lithium concentrate per year for export to China. There, the concentrate will undergo further transformations to make battery-grade lithium.

Phase 1

At the Sabi Star mine in Zimbabwe, a first processing stage aims to start separating the lithium content from the solid rock

Step 1

The ore, which contains on average 1.98% of lithium, is crushed into pieces.

Step 2

Step 3

Step 4

Phase 1

At the Sabi Star mine in Zimbabwe, a first processing stage aims to start separating the lithium content from the solid rock.

Step 1

The ore, which contains on average 1.98% of lithium, is crushed into pieces.

Step 2

Step 3

Step 4

Phase 2

Spodumene concentrate is then exported to China where it is further refined into battery-grade lithium in a complex process.

Step 5

Step 6

Step 7

Step 8

Step 9

Phase 2

Spodumene concentrate is then exported to China where it is further refined into battery-grade lithium in an energy-hungry process.

Step 5

Step 6

Step 7

Step 8

Step 9

President Mnangagwa, who inaugurated the processing plant in August, described it as “a significant step towards harnessing our nation’s mineral wealth for sustainable development”.

I am proud to officially commission the Sabi Star Lithium Mine, a significant step towards harnessing our nation’s mineral wealth for sustainable development. This mine’s potential will empower our economy and create opportunities for our people. pic.twitter.com/AiLvV8erX7

— President of Zimbabwe (@edmnangagwa) August 31, 2023

But producing lithium concentrate won’t be enough to spur the economic dividends the country needs. To fully reap the benefits of the energy transition, Zimbabwe must play a role in manufacturing the end product: batteries, said Darlington Muyambwa, of the Southern Africa Resource Watch.

While an awesome feat for a low-income country like Zimbabwe, Muyambwa said this could be achieved through regional cooperation. And there are signs Chinese investors are interested in providing financing. Eagle Canyon International, a Hong-Kong based company, is one of two Chinese investors which committed $2.8 billion to process lithium and other minerals to battery-grade level in Zimbabwe.

For opposition politician Elton Steers Mangoma, former energy and economic planning minister, this is Zimbabwe’s only pathway to development. “If we are not doing value addition as a country, we should leave the minerals underground for future generations, which might have the capacity to add value.”

Main image: Two men at work at the Sabi Star lithium mine. Photo: REUTERS / Philimon Bulawayo

Andrew Mambondiyani

Author

Bernard Chiketo

Chloé Farand