Sweden

Beyond lithium: how a Swedish battery company wants to power Europe’s green transition with salt

Martin Gelin

Meli Petersson Ellafi

Sweden

Beyond lithium: how a Swedish battery company wants to power Europe’s green transition with salt

Martin Gelin

Meli Petersson Ellafi

The Swedish company’s labs form the largest campus for battery research in Europe. It’s here, in a former industrial zone on the outskirts of the town of Västerås, about 100 kilometres northwest of the capital Stockholm, that one of the continent’s best-funded climate tech companies could write the future of batteries.

In November 2023, Northvolt – Europe’s only major home-grown EV battery maker – announced a breakthrough in battery development.

The company had manufactured a first-of-its-kind energy storage battery by replacing widely used critical minerals – such as lithium, cobalt, nickel and graphite – with cheaper and far more abundant sodium – a chemical element which is found in table salt – as well as iron, nitrogen and carbon.

“This is a fundamentally new technology,” Andreas Haas, head of Northvolt’s sodium-ion programme, told Climate Home News in an interview.

The timing of Northvolt’s innovation took the battery industry by surprise. According to Daniel Brandell, a materials chemist at Uppsala University in Sweden, technology roadmaps in North America and Europe had put this development closer to 2030 than prior to 2025.

While Chinese companies were first to use sodium to replace lithium in batteries, they often relied on other critical minerals such as nickel or cobalt to optimise their performance, Brandell said. Today, there is still limited transparency over the detailed performance and specific type of sodium-ion batteries Chinese companies are deploying.

Northvolt’s sodium batteries, however, are critical mineral-free.

In recent years, concerns have grown over the social and environmental harms of extracting and refining battery minerals. Reserves of lithium, nickel and cobalt are concentrated in a handful of countries, making them prone to geopolitical and trade disruptions, and subject to intense competition. Meanwhile, China dominates the lithium-ion battery supply chain, controlling 70% of global lithium refining capacity.

Sodium-based batteries offer a solution to the electric battery supply chain challenges, particularly for Western countries seeking to reduce their dependence on China for cleantech.

According to 2023 analysis by BloombergNEF, sodium batteries could displace 272,000 tonnes of lithium demand by 2035, equivalent to about 7% of the overall market projected for that year.

In January, the European Investment Bank backed the company with over $1 billion in financing, citing Northvolt’s ability to create the first fully integrated circular lithium-ion battery production facility outside Asia.

At the time, EU Commission Vice President Maroš Šefčovič, in charge of the European Green Deal, said the battery industry was of “strategic importance and a key battleground for global competitiveness”.

“Northvolt, our battery pioneer, showcases that the EU has what it takes to build an innovative, sustainable and globally competitive battery ecosystem,” he said.

The vision: regional battery hubs

Northvolt’s sodium batteries have been designed to store excess power generated by renewable energy such as wind and solar, and dispatch it back to the grid when it is most needed.

The International Energy Agency (IEA) says global energy storage capacity needs to increase six times for the world to achieve the goal of tripling global renewable capacity by 2030, with batteries expected to deliver 90% of that growth.

Sodium batteries, which are around 30% cheaper than lithium ones to produce, could account for about 10% of the added capacity by 2030 and keep rising after that, according to the IEA.

While the US holds 92% of the world’s sodium carbonate reserves, the chemical is the sixth most common element on Earth – 1,000 times more abundant than lithium – and is widely available in Europe. “The risk of dependence on US supply chains is low,” the company told Climate Home.

This could enable the creation of regional battery manufacturing hubs, which could help accelerate decarbonisation in emerging economies and developing countries.

“Because we’re not tied to a geography, we will no longer have to rely on lithium from mines in China or South America. We can produce these batteries all over the world,” said Haas.

With better resistance to high temperatures than lithium batteries, which are inherently flammable, sodium-ion batteries could help speed up electrification in regions exposed to extreme heat such as India, Africa and the Middle East by providing cheap and safe clean energy storage options.

Several Indian companies, including multinational conglomerate Reliance, are working to produce sodium batteries in the country. They could become “crucial” to India’s transition from coal to renewable energy by making energy storage “cheaper and more accessible,” Brandell, of Uppsala University, told Climate Home.

Northvolt said it will finalise its first sodium battery prototypes for energy storage later this year before developing a production line to manufacture them.

The destination: sodium-powered EVs

Over the last 30 years, lithium has been used to manufacture rechargeable batteries that are lightweight, compact, and yet can store a lot of energy.

Sodium, while cheaper and more abundant, is larger and heavier than lithium, making for bulkier batteries. That means sodium-ion batteries store a lower amount of energy than lithium ones of the same size. That might not be a problem for static energy storage but can become an issue for electric cars, as most drivers want to get more miles out of a single charge.

But despite sodium batteries’ lower energy density and the falling price of lithium, excitement around the technology has remained high.

China leads the world in manufacturing clean energy technologies and sodium-based batteries are no exception. There are nearly 30 sodium-ion battery manufacturing plants currently operating, planned or under construction globally – almost all of them in China. In May, the country put its first large-scale sodium-ion battery energy storage station into operation.

The country has shown that sodium batteries could still have a role to play in decarbonising road transport. Earlier this year, Chinese EV manufacturers launched small sodium-powered electric vehicles (EV) models, designed for short-range travel.

The IEA found that sodium-ion batteries could be used to power two-wheeled scooters and small EVs in cities, where drivers don’t require such long-range autonomy.

With a capacity of 160 watt-hours per kilogramme (Wh/kg), Northvolt said its sodium-ion battery is the best performing battery of its type on the market. However, more work is needed before it can power long-range EVs.

“We’re not yet ready for the European automotive market,” said Haas. But in a few years, Northvolt hopes to produce sodium-ion batteries with 180 Wh/kg capacity – packing the same amount of energy as some lithium batteries used in long-range electric cars, he added.

“This is a first-generation technology and we see so much potential in it. But the second generation will be even better,” Haas told Climate Home.

Mission to ‘make oil history’

Northvolt was started in Stockholm in 2016 by former Tesla employees Peter Carlsson and Paolo Cerutti, who shared the goal of making battery manufacturing more sustainable by creating “the world’s greenest battery”. The company is on a mission to“make oil history”.

“Renewable energy storage is the key to a carbon-neutral society, and batteries are the key to getting there,” Northvolt CEO Carlsson told the European Investment Bank (EIB) in 2018 after it offered the company a large investment.

The EIB loan contributed to the construction of the Västerås battery research facility, which opened the following year. The plant was intended to research and improve the lithium battery cell manufacturing process for mass production at Northvolt’s Skellefteå gigafactory, not far below the Arctic Circle in northeast Sweden.

It wasn’t long before the research focused on sodium battery development.

Together with a team of engineers, chemists and researchers from around the world, Haas worked closely with Altris, a Swedish battery developer and Northvolt’s research partner. Altris had achieved a breakthrough in battery chemistry by relying on research by Nobel Prize winning materials scientist John Goodenough and Japanese battery company Sharp, which together created Prussian White, the material used to manufacture the “negative” side of a sodium-ion battery, also known as the cathode.

“The issues that remained were energy density and moisture control. Northvolt came in and solved those two things”, increasing the battery’s performance to make it “commercially relevant,” said Haas.

A town of engineers

Kyrkbacken, a quaint downtown area of Västerås, where colourful 18th century houses line cobblestone streets, feels a world away from the glitzy hubs of green tech innovation.

Yet, Northvolt’s choice of a nearby location for its R&D centre was not for the town’s picturesque attributes. The city has a rich history of technical innovation and engineering, and is home to titan ABB, a leader in industrial electrification and automation, which has been based in the city for more than 100 years. It now provides machinery to Northvolt.

“It’s hard to overestimate the value of being in an existing ecosystem for engineering, chemistry and local industry while also being close enough to Stockholm for daily commuters,” Emma Nehrenheim, Northvolt’s chief environmental officer, told Climate Home during a visit of the labs.

A notable number of the company’s engineers have the distinct local twang of the Västerås area. Like others here, Nehrenheim calls herself an “ABB child” – a descendant from generations of local engineers who worked for the firm.

Nehrenheim said the company receives more than 10,000 work applications every month. “Northvolt is a purpose-driven company and this makes it easier for us to recruit internationally, especially with young people who are eager to find meaningful work,” she said.

Expansion plans

For Hughes, of battery consultancy Rho Motion, Northvolt is well placed to bring its sodium-ion storage batteries into large-scale factory production.

The company has received billions in funding from investors such as Goldman Sachs, BlackRock, Volkswagen and the Swedish Energy Agency and secured $55bn in lithium-ion battery orders from major car makers, such as BMW, Scania, Volvo and Volkswagen. At the start of 2024, Northvolt raised $5bn worth of debt – which it described as Europe’s largest-ever green loan – to expand its Skellefteå battery factory and finance its recycling efforts. This included over $1bn from the EIB.

In April this year, Northvolt opened its first factory for producing sodium-ion batteries at its manufacturing facility in Skellefteå, with additional plants being planned in Canada, Germany and across Sweden, it said.

Northvolt told Climate Home the delays will have no impact on the advancement of sodium batteries, citing “separate production and also a separate team working on the technology”.

Closing the supply chain loop

While still in the early stages of development, Northvolt’s sodium-ion batteries could become pivotal to the company’s sustainability strategy.

By 2030, the company says it wants to bring down the carbon emissions embedded in the battery production process by 90%. For now, recycling and reusing materials for its lithium-ion batteries are key to Northvolt’s plans to meet the goal.

Nehrenheim, Northvolt’s chief environmental officer, said the company is able to recycle around 95% of a lithium-ion battery’s materials, which can then be used again in its production process, creating a circular supply chain.

By 2030, the company wants all its new battery cells to be produced with 50% recycled material. Sodium, which is easier and more cost-effective to recycle than lithium, could help the company reach future recycling goals.

“We live on a planet with a finite number of natural resources. To accommodate future demand and sustain ethical supply chains, we need to recycle more,” said Nehrenheim. “We can already recycle 95% of battery materials. We’ll soon reach 100% and then we can use a battery for infinity.”

“We will continue our work with Sodium ion batteries at Northvolt Labs. We are still in early development of that specific technology so no large-scale production is going on, it’s mainly on lab scale work.”

Update: In September 2024, Northvolt announced it would cut 1,600 jobs across its operations in Sweden amid a slowdown of the EV market. The company said it would focus on scaling battery production at its gigafactory in northern Sweden.

The expansion of the Västerås site will be slowed down, Northvolt said, but battery innovation will be maintained. A spokesperson told Climate Home: “We will continue our work with sodium-ion batteries at Northvolt Labs.”

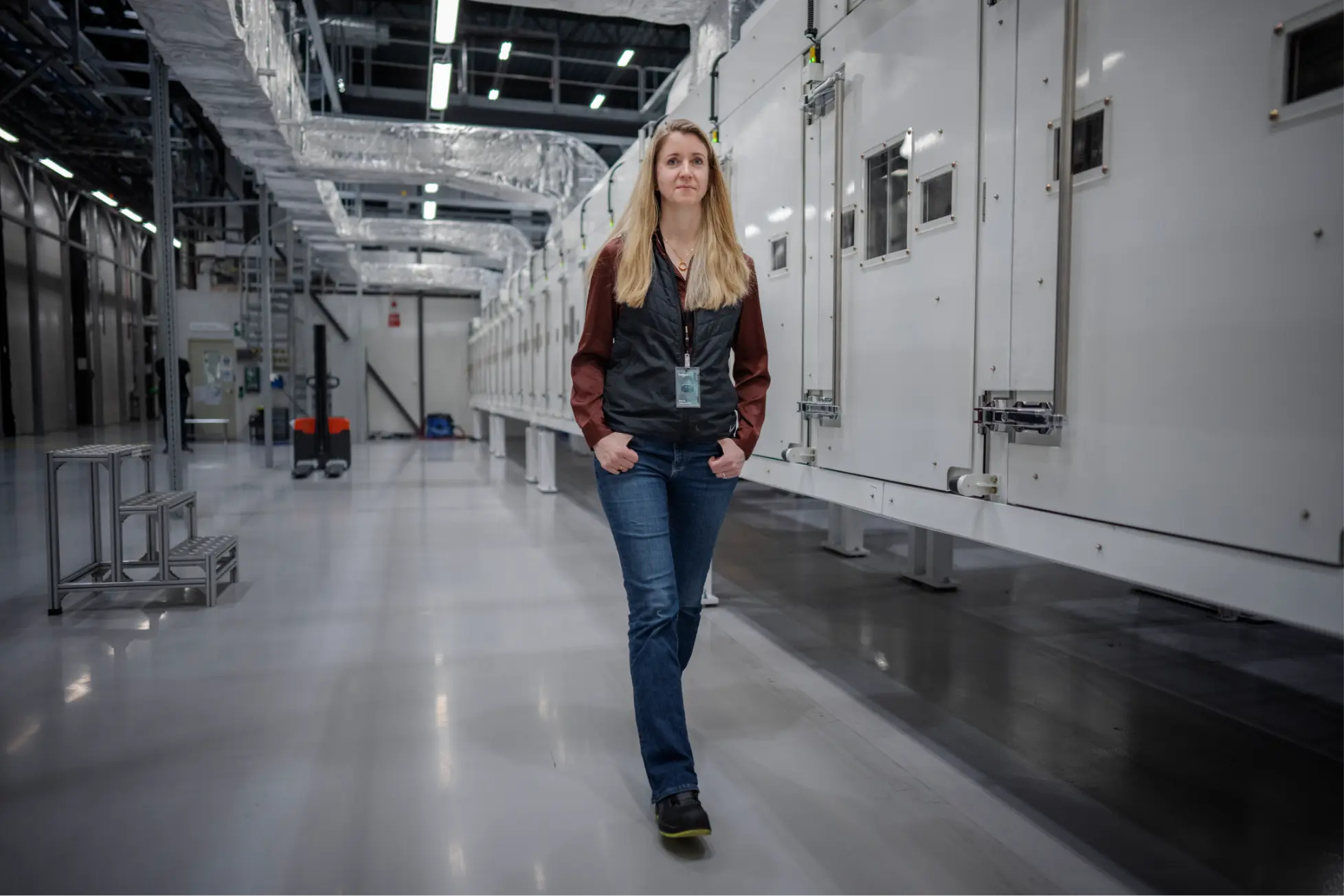

Main image: A Northvolt employee at the company’s battery research labs outside Västerås, Sweden

Martin Gelin

Meli Petersson Ellafi

Chloé Farand